ADDITIVE MANUFACTURING

How does additive manufacturing function?

The term "additive manufacturing" encompasses technologies that build three-dimensional objects by layering superfine materials sequentially. Each subsequent layer adheres to the previous layer of either melted or partially melted material. Objects are digitally defined using computer-aided design (CAD) software, which generates .stl files that essentially "slice" the object into ultra-thin layers. This information guides the movement of a nozzle or print head, accurately depositing material onto the existing layer. Alternatively, a laser or electron beam can selectively melt or partially melt a bed of powdered material. As the materials cool or cure, they fuse together to form a complete three-dimensional object.

Processes of additive manufacturing

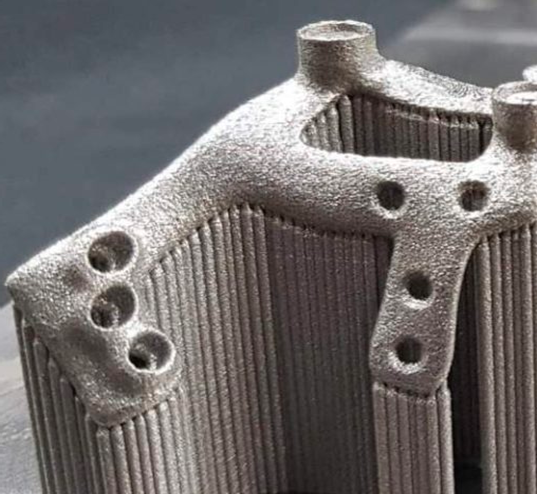

Powder Bed Fusion

Powder Bed Fusion (PBF) technology is utilized in various Additive Manufacturing (AM) processes, including Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Selective Heat Sintering (SHS), Electron Beam Melting (EBM), and Direct Metal Laser Melting (DMLM). These systems employ lasers, electron beams, or thermal print heads to melt or partially melt ultra-fine layers of material within a three-dimensional space. As the process concludes, excess powder is blown away from the object.

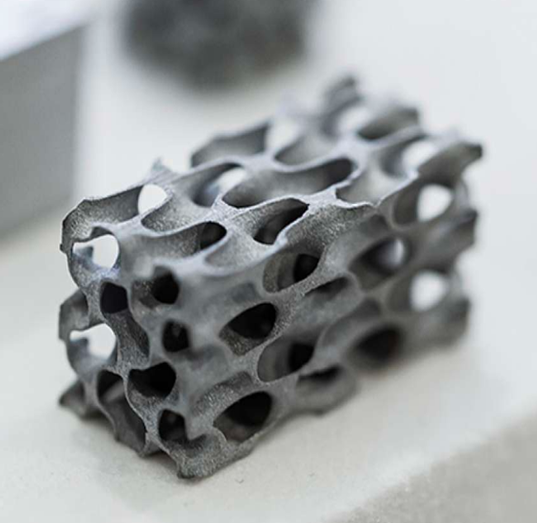

Binder jetting

Binder Jetting is an additive manufacturing technique where an industrial printhead precisely applies a liquid binding agent onto a slim layer of powder particles, which can be composed of metal, sand, ceramics, or composites. This method is employed to construct unique and high-value parts and tooling. The process iterates layer by layer, following a digital design file, until the final object is fully formed.

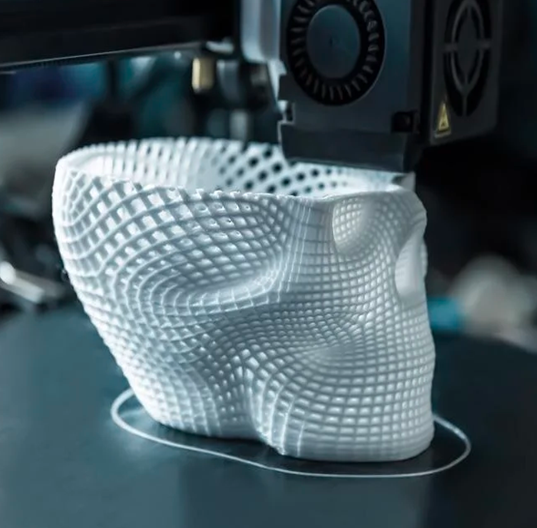

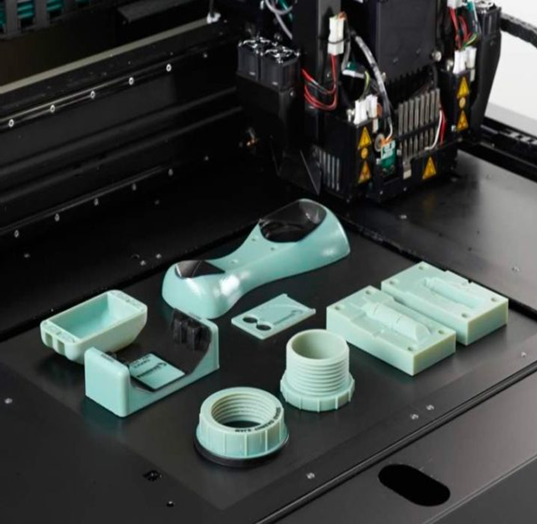

Material extrusion

Material extrusion stands out as one of the most widely recognized additive manufacturing processes. In this method, spooled polymers are either extruded or drawn through a heated nozzle affixed to a movable arm. The nozzle moves horizontally, while the bed shifts vertically, facilitating the construction of layers of melted material. The cohesive bonding between layers is achieved through meticulous temperature control or the application of chemical bonding agents.

Directed Energy Deposition

The process of Directed Energy Deposition (DED) is akin to material extrusion, but it is applicable to a broader range of materials, encompassing polymers, ceramics, and metals. A four- or five-axis arm, equipped with an electron beam gun or laser, is utilized to melt either wire, filament feedstock, or powder.

Material jetting

In material jetting, a print head traverses back and forth, similar to the mechanism of a 2D inkjet printer. Nevertheless, it commonly moves along the x-, y-, and z-axes to produce 3D objects. The layers solidify as they cool or undergo curing via ultraviolet light.

Vat photopolymerization

In the process of vat photopolymerization, an object is generated within a vat containing liquid resin photopolymer. Photopolymerization, facilitated by ultraviolet (UV) light precisely directed by mirrors, cures each microfine resin layer.

Talk to us

Have any questions? We are always open to talk about your business, new projects, creative opportunities and how we can help you.